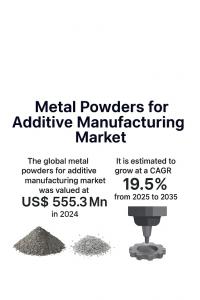

Metal Powders for Additive Manufacturing Market on Track for USD 3.9 Billion Valuation by 2035

The metal powders for additive manufacturing market was valued at US$ 555.3 Mn in 2024”

WILMINGTON, DE, UNITED STATES, September 16, 2025 /EINPresswire.com/ -- The global metal powders for additive manufacturing market was valued at USD 555.3 million in 2024 and is projected to reach nearly USD 3.9 billion by 2035, expanding at a strong CAGR of 19.5% during the forecast period. Growth is primarily driven by rising adoption across aerospace, defense, healthcare, and automotive industries, where the demand for lightweight, high-strength, and complex components is accelerating.— By Transparency Market Research

Titanium, stainless steel, nickel alloys, and aluminum powders are leading the adoption curve, each bringing unique benefits such as strength, corrosion resistance, or weight reduction. Additionally, innovations in atomization techniques and powder recycling are improving efficiency while reducing costs and environmental impact.

Access the Sample Report – Discover Key Market Highlights: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=33197

Key Players:

• Höganäs AB

• Sandvik

• RIO Tinto Metal Powders

• Kennametal Inc.

• GE Additive

• Carpenter Technology Corporation

• Aubert & Duval

• Elementum 3D

• Metalysis

• GKN Powder Metallurgy

• ATI

• Markforged

• Renishaw

• Linde PLC

• Astro Alloys Inc.

• EOS GmbH

• Oerlikon AM

• Tekna Advanced Materials Inc.

• VDM Metals GmbH

• TRUMPF

• SSAB

Key Growth Drivers

Aerospace and Defense Adoption

Aircraft engine parts, fuel nozzles, and lightweight structural components are being manufactured using metal AM to improve performance and reduce fuel consumption. Defense applications, where precision and strength are critical, further bolster demand.

Healthcare and Medical Implants

Personalized implants, prosthetics, and dental products represent one of the fastest-growing segments. Titanium powders dominate this space due to their biocompatibility, durability, and adaptability to complex structures.

Automotive Sector Integration

Carmakers are exploring metal AM to create lighter, stronger parts, enhancing efficiency and performance. As electric vehicles (EVs) grow in popularity, demand for lightweight materials will accelerate further.

Technological Advancements

Breakthroughs in powder bed fusion, binder jetting, and direct energy deposition technologies are expanding the usability of metal powders across industries. Improved particle morphology, flowability, and powder consistency are ensuring higher-quality builds.

Sustainability and Circular Economy

Powder recycling and reuse strategies are addressing the high costs associated with metal powders. Sustainability considerations are becoming central to procurement and production decisions in advanced manufacturing ecosystems.

Regional Insights

North America remains a hub for aerospace and medical applications, with high adoption of certified powders and advanced process technologies.

Europe is focusing on sustainable manufacturing and innovation, supported by strong aerospace and healthcare industries.

Asia-Pacific is expected to grow at the fastest pace, driven by increasing industrialization, government support, and large-scale investments in additive manufacturing technologies.

Latin America and the Middle East & Africa are emerging markets with growing demand for advanced manufacturing, particularly in automotive and energy sectors.

Competitive Landscape

The market is highly competitive, with both established metallurgical giants and innovative startups contributing to growth. Leading players are focusing on:

Expanding alloy portfolios to meet diverse industry needs.

Investing in R&D for novel powders such as high-entropy alloys and refractory metals.

Developing cost-efficient atomization processes to reduce production costs.

Forming strategic collaborations with aerospace, automotive, and healthcare manufacturers to strengthen market presence.

Challenges and Restraints

High Production Costs: Producing high-quality powders with strict control over particle size, purity, and morphology remains expensive.

Certification Barriers: Aerospace and medical applications demand rigorous certification, lengthening time-to-market for new powders.

Supply Chain Volatility: Dependence on raw material availability and geopolitical dynamics poses risks to supply and pricing stability.

Energy-Intensive Processes: Powder production techniques such as gas and plasma atomization require high energy input, raising sustainability concerns.

Future Opportunities

Novel Alloy Development – High-entropy and hybrid alloys are expected to revolutionize performance in critical applications.

Mass Production via Binder Jetting – Cost-effective and scalable, binder jetting is opening new opportunities for mass adoption of metal powders.

Digital Integration – Data analytics, AI, and simulation technologies are being employed to optimize powder use and predict material performance.

Localized Manufacturing – Distributed AM centers with local powder supply chains will reduce costs and improve responsiveness.

Green Manufacturing – Growing emphasis on sustainable production and recycling is creating competitive differentiation.

More Trending Reports by Transparency Market Research –

Waterproofing Membranes Market - https://www.transparencymarketresearch.com/waterproofing-membrane-market.html

Floor Coatings Market - https://www.transparencymarketresearch.com/floor-coatings-market.html

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: sales@transparencymarketresearch.com

Atil Chaudhari

Transparency Market Research Inc.

+1 518-618-1030

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.